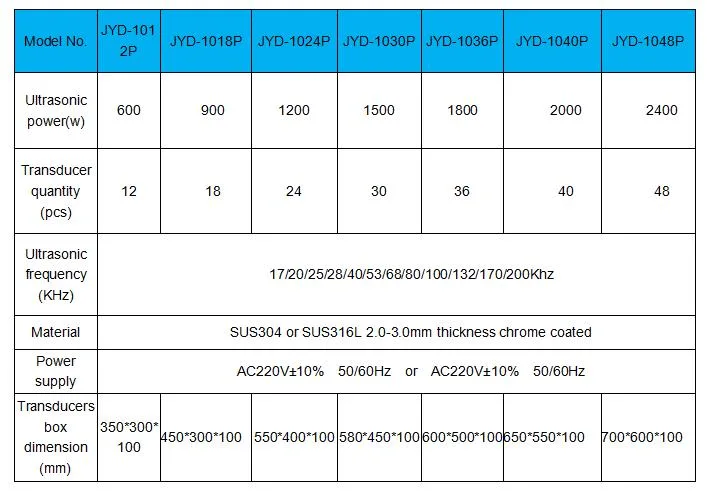

Jyd1012p MCU Sweep Constant Power Output Submersible Ultrasonic Vibration Plate Immersible Transducers Plate For Ultrasonic Cleaner Tank

Features:

1. It is made of thick SUS304 or SUS316L stainless steel, chrome-plated on the vibration surface, and double-pulse technology for better sealing performance.

2. Adopt automatic frequency chasing, MCU-SWEEP constant power output ultrasonic generator drive, ultrasonic cleaning is even and strong.

3. Adopts industrial grade high Q value transducer, imported high-strength glue bonding, the ultrasonic cleaning conversion efficiency is higher.

4. It can be 24 hours, which is suitable for mass production continuous work

5. Strict production industry and aging industry, the whole machine 2500V high voltage test, the products have passed CE, FCC, ROSH and other certifications.

6. It can be customized according to the actual needs of customers, immersed ultrasonic transducers with different specifications, different sizes, power and frequency.

Application:

Plating lines for the metal parts, or for cleaning the PCB, electronic parts, auto parts, engine parts, injector, air cylinder, mould, blind window, filter elements, anilox roller, screw, nuts, bullet shell, printer and other industrial parts so on.

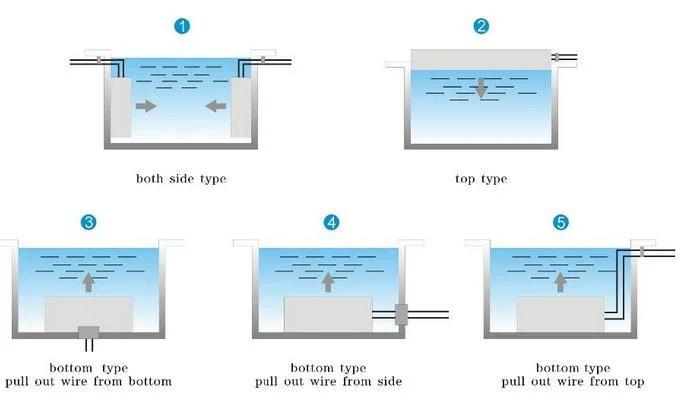

Submersible ultrasonic transducers can be installed in the tank by three ways as below, the fix way is customized.

Q: How to choose the frequency?

A: Ultrasonic cleaners operate at very low frequencies (within the human hearing range) and produce noise. When the frequency is below 20 kHz, the working noise not only becomes very large, but may exceed the limits of safety noise as stipulated by occupational safety and health laws or other regulations. In applications where high power is required to remove dirt without regard to surface damage of the workpiece, lower cleaning frequencies ranging from 20 kHz to 30 kHz are typically selected. Cleaning frequencies in this frequency range are often used to clean large, heavy-duty or high-density workpieces.

Low frequencies are often used to clean smaller, more delicate parts or to remove tiny particles. High frequencies are also used in applications where damage is not allowed on the surface of the workpiece. The use of high frequencies improves cleaning performance in several ways. As the frequency increases, the number of cavitation bubbles increases linearly, producing more denser shock waves that allow them to enter smaller gaps. If the power remains the same, the cavitation bubbles become smaller and the energy released is correspondingly reduced, thus effectively reducing the damage to the surface of the workpiece. Another advantage of high frequency is the reduced viscous boundary layer

Q: How to ensure the durable of the ultrasonic transducers box?

A: The transducer will not fall off when the vibration plate works for a long time effectively, because our vibration adhesive has the following characteristics:

1. Gray paste, with good gap filling ability;

2. Room temperature curing, 35 minutes of applicable time, 4 hours of initial solid, 8 hours can be moved;

3. Especially suitable for adhesion and sealing of various ultrasonic vibrators and stainless steel panels;

4. High hardness, low shrinkage, low volatile loss rate after curing, good chemical resistance and high temperature resistance (up to 120 degrees Celsius);

Ultrasonic vibration plate first-class transducer bonding technology, can ensure that no degumming worry, so that the sound wave conduction path unblocked.Excellent resistance to high temperature performance can make the vibration plate in 100 ºC water medium and long-term stable job.

Guarantee and Service:

We provide the product with warranty which is valid for one year from the purchase date, during which, any breakdown or failure of any component in the product will be subject to repair service free of charge.